I keep adding more tools to my tool box, and expanding the knowledge of the tools already in use. It is why I have some many projects going on. I want to learn new things or more about things I already know. I continue to invest in learning FreeCAD. The tool amazes me, each time I use it. I find it better and easier to use. Practice practice practice… Pick a tool and use it. Well I’ve been tinkering with Tinkercad too, but with some residual AutoCAD skills from my school days. I am more comfortable in the FreeCAD interface and methodologies.

I had always used OpenSCAD either standalone on in FreeCAD workbench, as my go to design tool. Today I started testing an new module LCInterlocking for FreeCAD. It is why the open source community is so great. Great tool and then people invest their time to make modules for it to make it greater. This tool seamlessly integrated into FreeCAD and has its own workbench and easy to follow video tutorials.

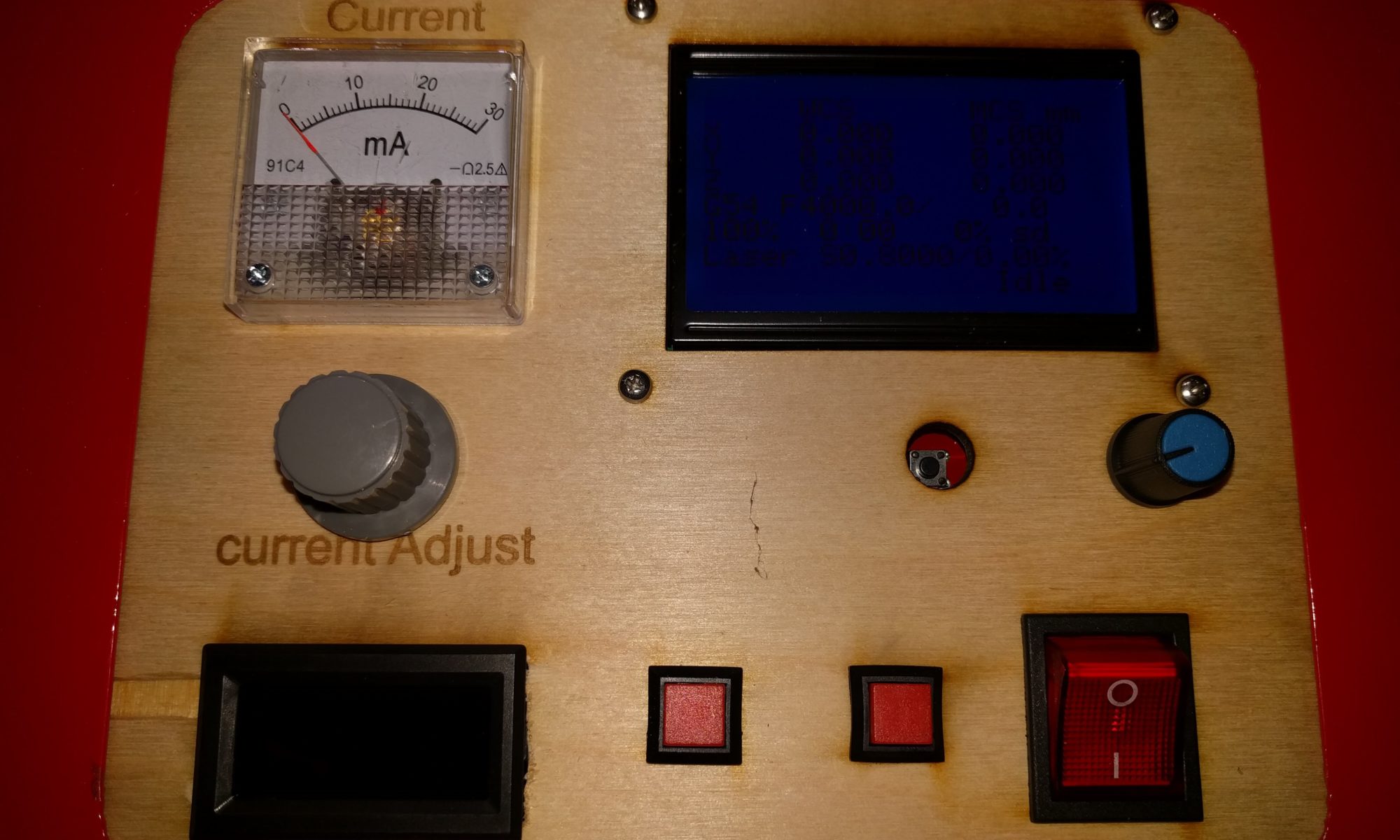

I still need to work on my Industrial Design but the new box has better tab strength and a slot for all connection access. It is a little less visually appealing, but I though the original revision the tabs were too small. The kerf on the cut was too tight and the box was very tight to assemble. I may need to adjust the laser cutter’s focal length to prevent tapper in the cuts.

I know what your thinking. I should have added a place to include the switches in the box with access like these. That is why you build projects to learn new tools and how to best utilize them. I will just use the painter’s tape to hold them on top for now.